- Sie befinden sich hier:

- Products

- »

- Plastic injection-moulded parts

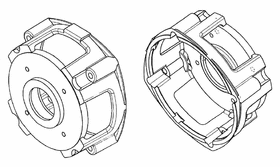

These plastic parts meet the highest demands and can be supplemented by inserting components, which are integrated, accurately fitting, in the moulding process. The components are produced strictly according to drawings supplied by the customer.

Due to the very competitive wage costs in China we are able to offer to our small and medium-sized customers access to first-class plastic injection moulds and, at the same time, low-cost injection moulds, which are able to produce exclusively high-class plastic parts. At the same time, due to these competitive wage costs, it is possible to insert components into the mould without any extra cost, which subsequently are integrated into the component during the injection-moulding process. The customer can choose, which standard material is to be used, and even special material mixtures can be processed on request.

Branch

- Motorcycle

- Automotive

- Machine building

- Gardening equipment

- Lighting technology